The difference of High-Pressure Homogenization vs. Sonication

The difference of High-Pressure Homogenization vs. Sonication

Homogenization is a crucial step in various industrial processes, including pharmaceuticals, food, and cosmetics. High-pressure homogenization (HPH) and sonication are two common homogenization techniques, but HPH offers several distinct advantages over sonication, especially when used with Genizer's high-pressure homogenizers.

Homogenization is a crucial step in various industrial processes, including pharmaceuticals, food, and cosmetics. High-pressure homogenization (HPH) and sonication are two common homogenization techniques, but HPH offers several distinct advantages over sonication, especially when used with Genizer's high-pressure homogenizers.

Smaller Particle Sizes

One of the most significant advantages of HPH over sonication is its ability to produce smaller particle sizes. HPH operates at much higher pressures and forces the sample through a narrow valve, resulting in a more intense and efficient homogenization process. This leads to smaller particle sizes, which can improve product quality, increase bioavailability, and enhance downstream processing steps such as filtration or extraction.

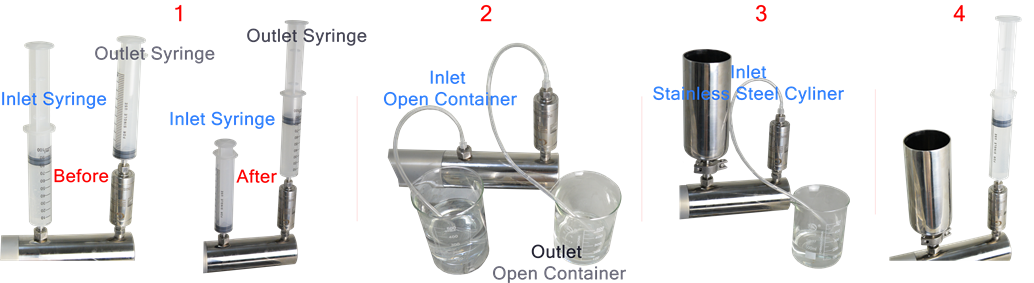

Using NanoGenizer experimental microjet high pressure homogenizer to homogenize samples

(Left: before homogenization, Right: after homogenization)

Scalability and Energy Efficiency

Another advantage of HPH over sonication is its scalability and energy efficiency. HPH systems can process larger volumes of material, making it a more efficient and cost-effective option for industrial-scale processing. Additionally, HPH is a more energy-efficient process than sonication, which can result in significant cost savings over time.

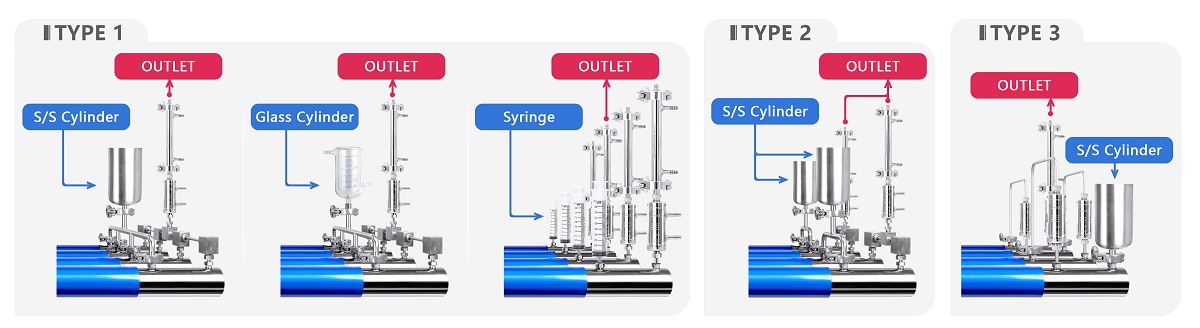

Connectable basic fittings of NanoGenizer series microfluidic high pressure homogenizer

Connectable basic fittings of Genizer series microfluidic high pressure homogenizer

NanoGenizer microfluidic high pressure homogenizer combines with online liposome extruders

Gentler Processing Conditions

Finally, HPH can be a gentler process than sonication, particularly when processing delicate samples like pharmaceuticals or biologics. Sonication generates heat and cavitation, which can damage sensitive compounds and reduce product quality. In contrast, HPH provides more precise control over processing conditions, allowing for a gentler and more consistent homogenization process.

When it comes to high-pressure homogenization, Genizer's high-pressure homogenizers are among the most reliable and efficient options in the market. With advanced technology and user-friendly designs, Genizer's homogenizers offer precise control over processing parameters, enabling efficient and gentle processing of various samples.

In conclusion, while sonication can be a useful tool for processing samples, HPH offers several advantages over sonication, including smaller particle sizes, scalability, energy efficiency, and gentler processing conditions. By using Genizer's high-pressure homogenizers, these advantages can be maximized, making HPH a preferred choice for industrial-scale processing in various fields.

Finally, HPH can be a gentler process than sonication, particularly when processing delicate samples like pharmaceuticals or biologics. Sonication generates heat and cavitation, which can damage sensitive compounds and reduce product quality. In contrast, HPH provides more precise control over processing conditions, allowing for a gentler and more consistent homogenization process.

When it comes to high-pressure homogenization, Genizer's high-pressure homogenizers are among the most reliable and efficient options in the market. With advanced technology and user-friendly designs, Genizer's homogenizers offer precise control over processing parameters, enabling efficient and gentle processing of various samples.

In conclusion, while sonication can be a useful tool for processing samples, HPH offers several advantages over sonication, including smaller particle sizes, scalability, energy efficiency, and gentler processing conditions. By using Genizer's high-pressure homogenizers, these advantages can be maximized, making HPH a preferred choice for industrial-scale processing in various fields.

USD

USD 949-932-0294 Los Angeles

949-932-0294 Los Angeles  Nano@Genizer.com

Nano@Genizer.com